From steel to semifinished products tecscience

Continuous casting is a metal casting process that produces continuous lengths of metal, with a constant (2D) cross-section. It's a highly efficient method for converting molten metal into long lengths of semi-finished product of a relatively small, potentially complex cross-section.

Continuous casting Modern techniques to solve an old industrial

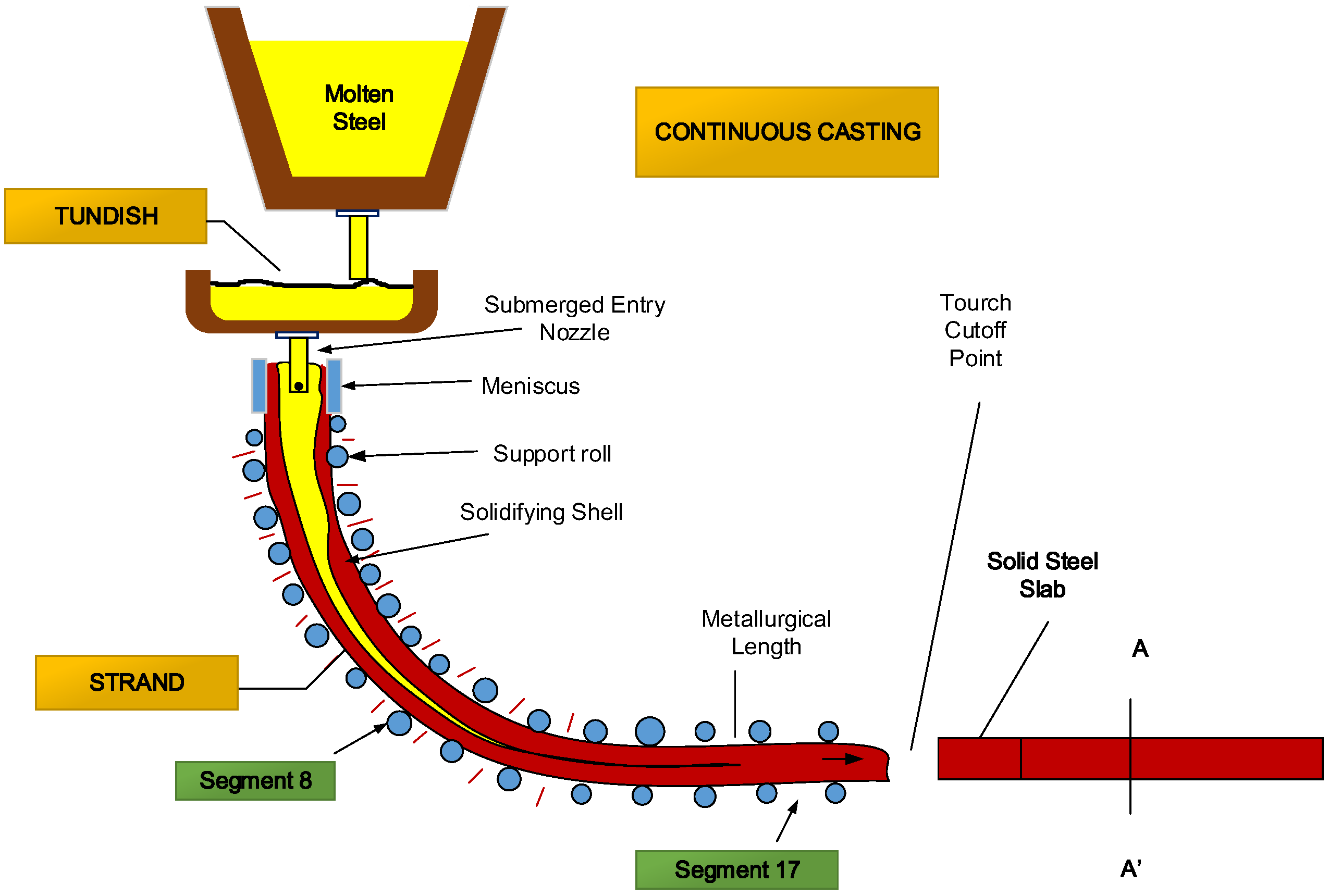

Continuous casting (CC) of steel is a process whereby liquid steel is solidified into a semi-finished steel product (billet, bloom, beam- blank, round or slab) for subsequent rolling in the rolling mills. The basic operation of a CC machine is to convert liquid steel of a given composition into a strand of desired shape and size through a group.

Optimizing the Continuous Casting Process with Simulation COMSOL Blog

Continuous steel casting is a process to obtain casting billets by the molten steel casted into the caster, solidifying, and cutting. It is a process between steelmaking and rolling, also called continuous casting for short. The steel billets produced by continuous casting are raw materials for various products in hot rolling mills.

Metalchic Atlas Bronze A Guide to Continuous Casting

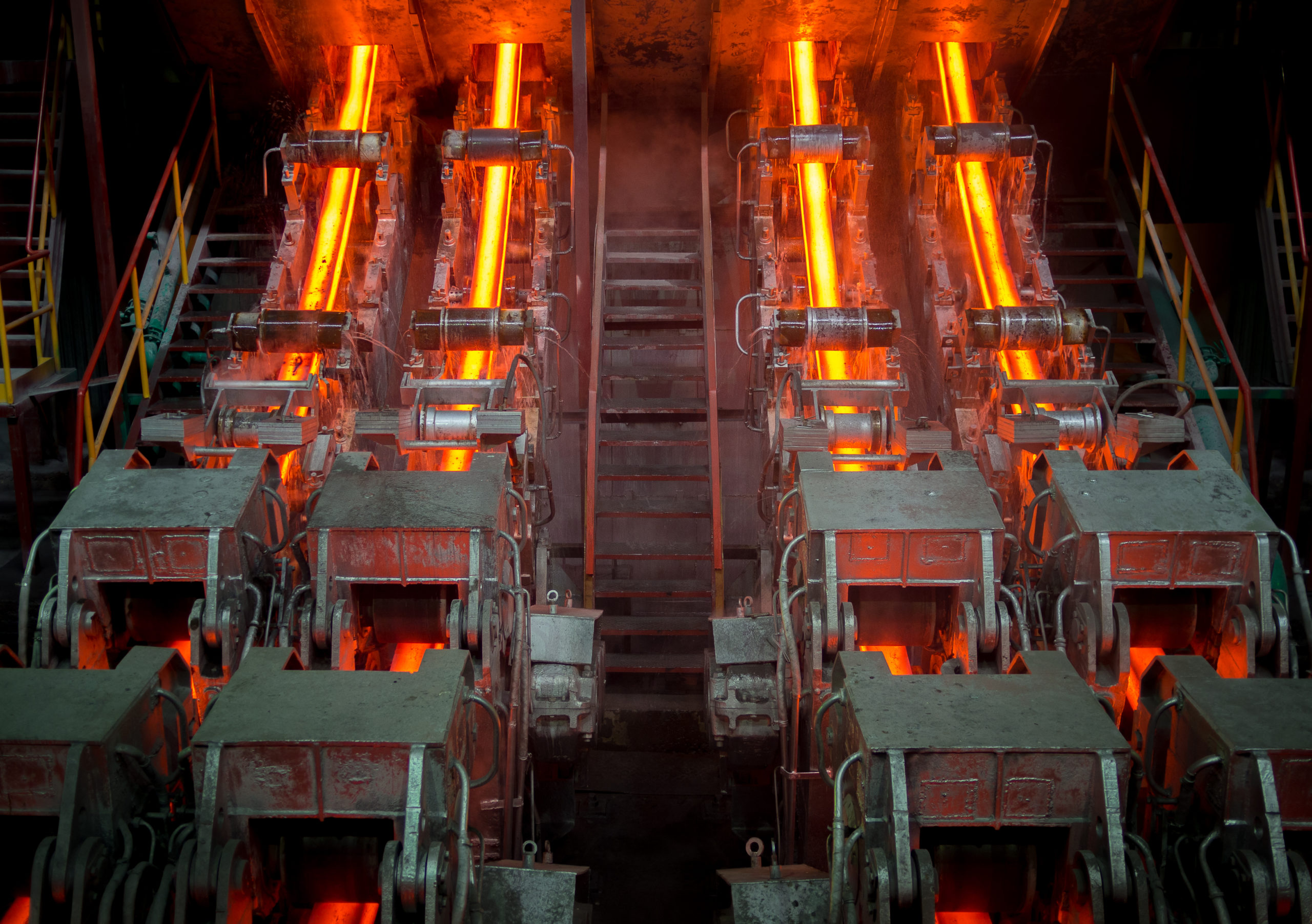

Continuous casting About 55 percent of the world's liquid steel production is solidified in continuous casting processes, the most widely used of which feeds liquid steel continuously into a short, water-cooled vertical copper mold and, at the same time, continuously withdraws the frozen shell, including the liquid steel it contains.

Metals Free FullText Continuous Casting

The Continuous Casting Consortium (CCC) encompasses a cooperative research effort between the University of Illinois, the Steel Industry, and the Government (NSF Project).Its purpose is to develop comprehensive mathematical models of the continuous casting of steel slabs and to apply these models to improve understanding, optimize the process, and solve practical problems of interest to the.

Steel Billet Continuous Casting MachineCooldo

Continuous casting is used to solidify most of the 750 million tons of steel produced in the world every year. Like most commercial processes, continuous casting involves many complex interacting phenomena. Most previous advances have been based on empirical knowledge gained from experimentation with the process. To further optimize the design and improve the continuous casting process.

From steel to semifinished products magnesite carbon bricks supplier

The process of continuous casting of steel is a complex technological task, including issues related to heat transfer, the steel solidification process, liquid metal flow and phase transitions in the solid state.

Continuous Casting Machine (CCM) for Foundry and Steel Making China

Continuous casting is the most important route for the production of steel today. Due to the physical, mechanical, and chemical components involved in the production, continuous casting is a very complex process, pushing conventional methods of monitoring and control to their limits.

continuous casting in steel making YouTube

Continuous casting is the important linking process between steelmaking and rolling. As early as 1856, Henry Bessemer suggested a continuous casting method but just during the 1930s and 1940s continuous casting became a common production method for nonferrous metals and later from the 1960s for steels.

Schematic of continuous casting process Download Scientific Diagram

Continuous casting transforms molten metal into solid on a continuous basis and includes a variety of important commercial processes. These processes are the most efficient way to solidify large volumes of metal into simple shapes for subsequent processing.

Continuous casting Find suppliers, processes & material

The steel continuous-casting process and the digital computer appeared at about the same time in history. Continuous casting has grown to produce over 95% of steel in the world[1]. Similarly, computational modelling has grown due to tremendous advances in computer power and to great improvements in the sophistication of modelling software.

Materials Free FullText A New Predictive Model of Centerline

Continuous casting practices for steelmaking have been constantly evolving ever since the early 1930s, when Junghans was first researching ways to pour liquid steel into an open-bottomed, water-cooled mold, to withdraw the partially solidified steel out of it, continuously, in the form of a round or square billet or slab [1,2].

(PDF) Breakout Problems Study of Continuous Casting Steel

Continuous casting, also called strand casting, is the process whereby molten metal is solidified into a "semifinished" billet, bloom, or slab for subsequent rolling in the finishing mills. Prior to the introduction of continuous casting in the 1950s, steel was poured into stationary molds to form ingots.

Continuous Casting, सतत कास्टिंग मशीन in Bistupur, Jamshedpur , Hitech

Wang Q, Shi YM, Wang F. Investigation of fluid flow and heat transfer in a continuous casting tundish with channel type induction heating using mathematical modeling and water modeling.. A two-phase 2D finite element model for macrosegregation in steel continuous casting. In: Jones H. editor, Proceedings of SP07 5th Decennial International.

Continuous Steel Casting with Syalon Break Rings

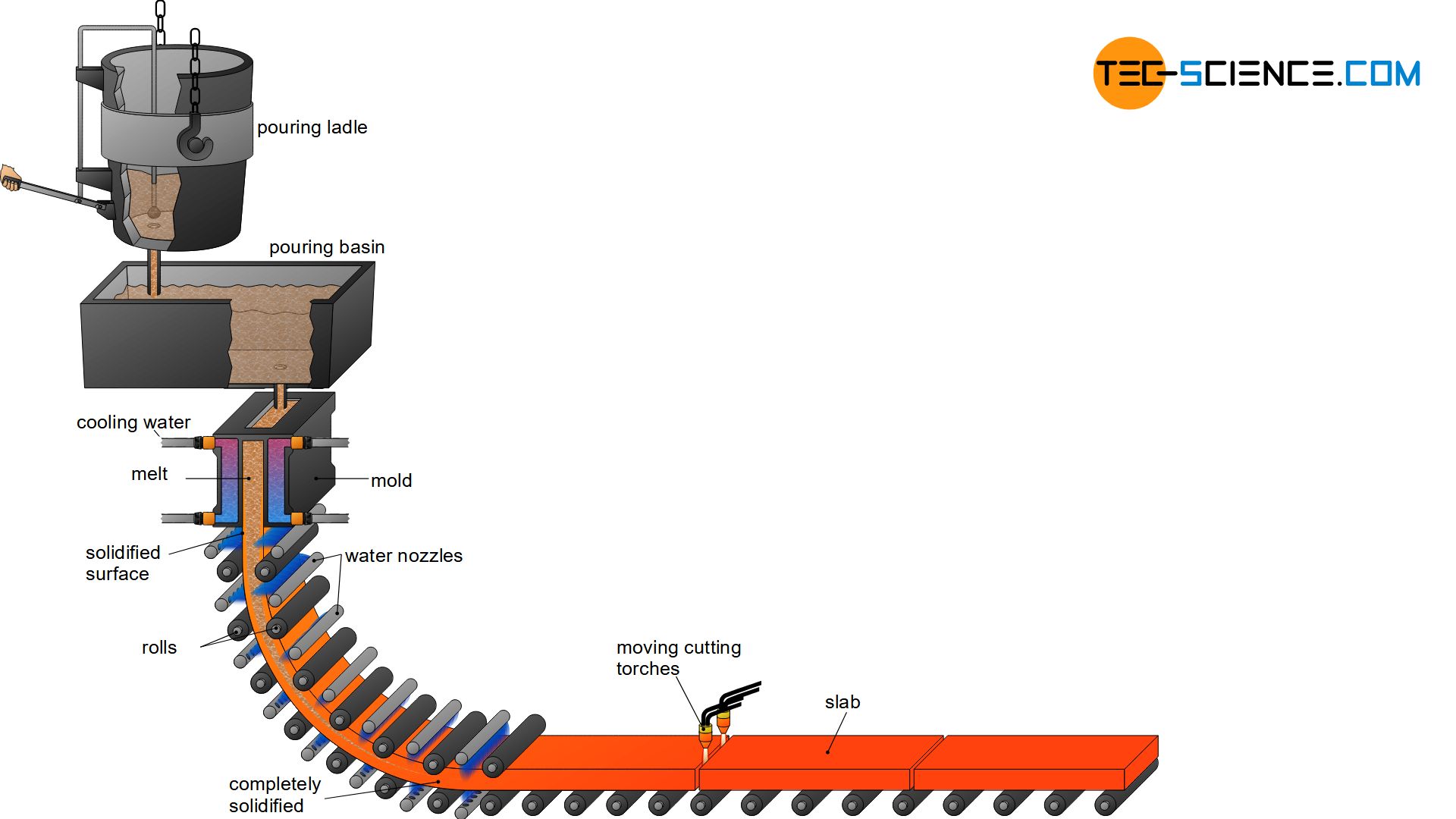

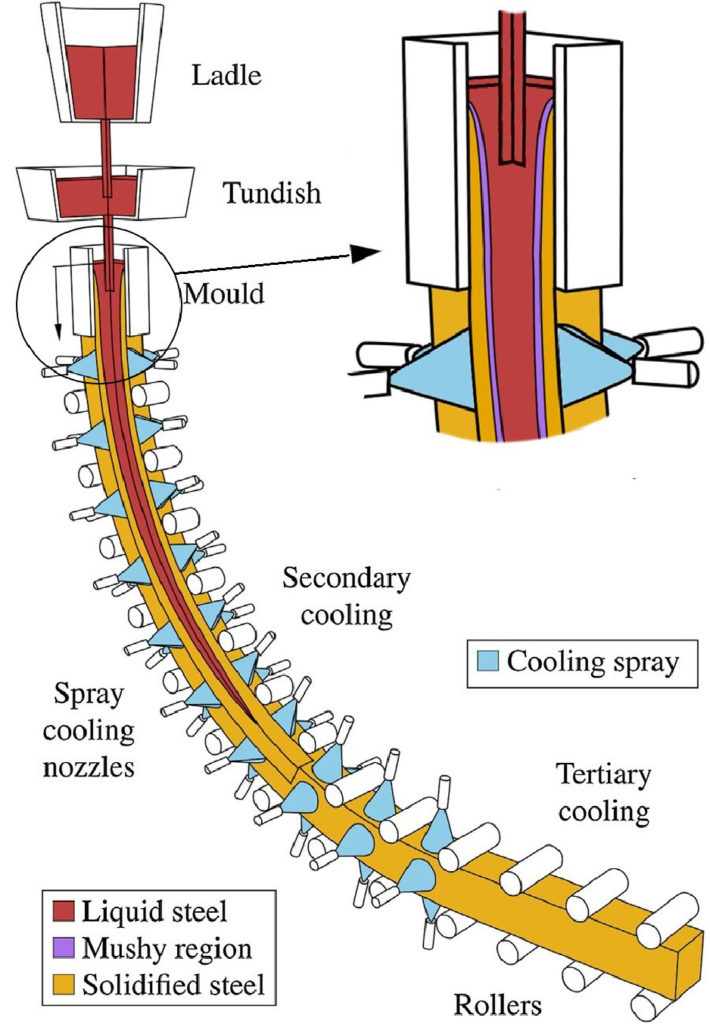

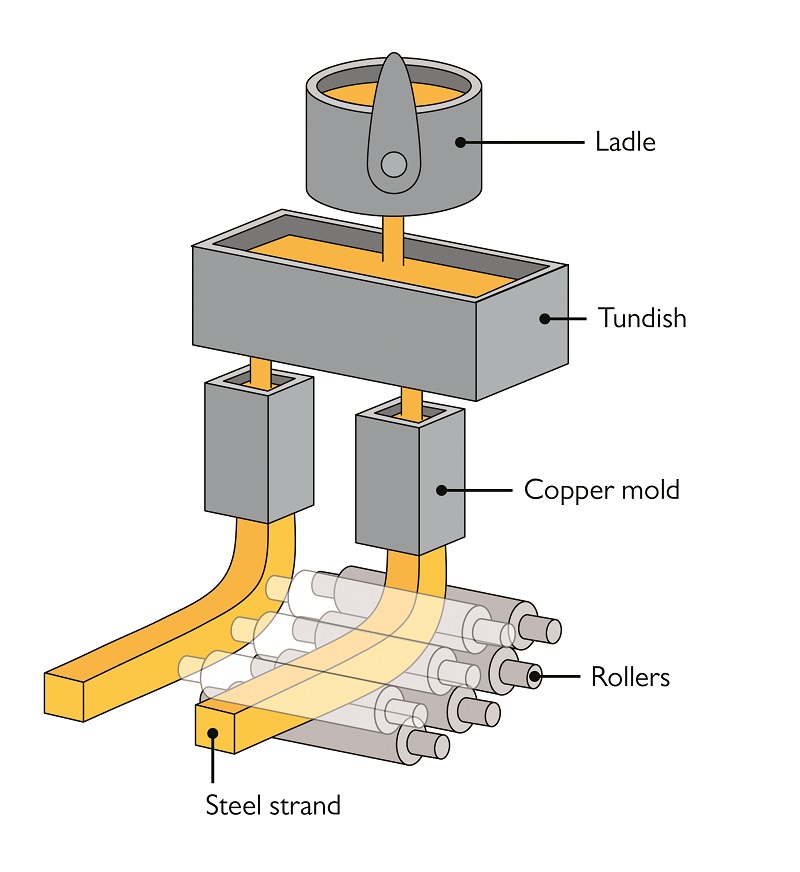

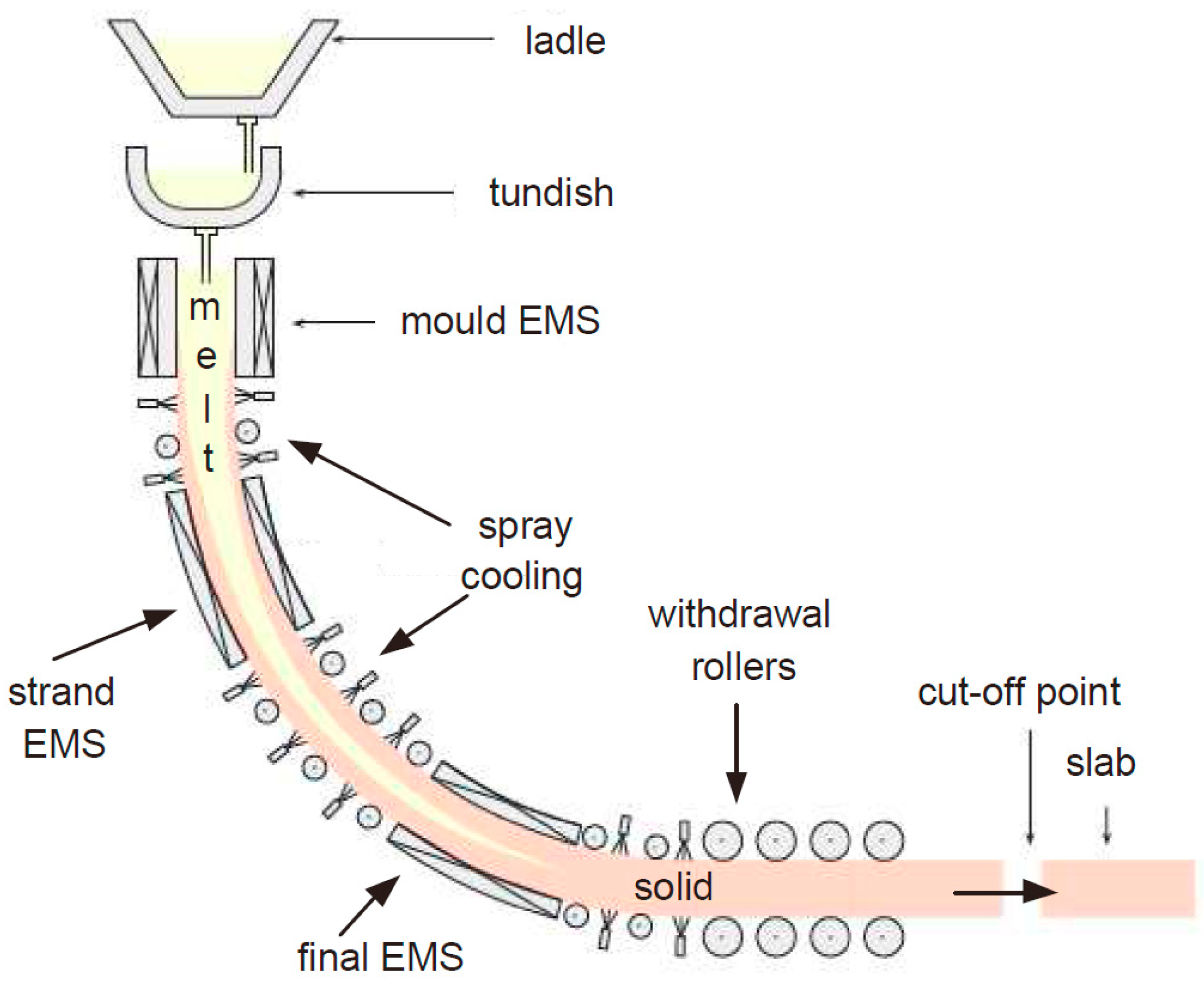

The continuous casting process is shown in Figure 1.9.1. Steel is poured from the ladle into the tundish, which provides a constant head for molten steel to flow from the tundish into the mold via a submerged entry nozzle (SEN). The copper mold is water-cooled and the bottom of the mold is initially sealed by a dummy bar of steel.

Continuous Casting Of Steel Stock Illustration Download Image Now

Continuous casting (CC) is a sophisticated metallurgical process used to manufacture most of the technological steel products (including billets, blooms, and slabs) around the world.